Shaker Cabinets: Your Hardware Placement Guide

Shaker Cabinets: Your Hardware Placement Guide Table of Contents Hardware cabinet placement is a critical part of bringing the aesthetics of a room together. But

There are many different variables to creating and running a successful cabinetry business. Whether designing & building cabinets, installing cabinets, or a combination of both, a business owner needs to constantly be on the lookout for ways to make their operation more efficient and hopefully more successful. One way to do this is by streamlining the measurement and installation process of cabinet hardware such as handles, knobs, and pulls. There are two main professional options on the market now – cabinet hardware templates and cabinet hardware jigs. Which one is best for your business though?

While they both serve a similar end-purpose, these two tools share an important difference. Templates are fixed patterns, essentially, in that every hardware placement laid out with the template will be identical to other hardware placements. Cabinet hardware jigs are adjustable, and be reconfigured by the user to mount different types of hardware or to accommodate different cabinet or drawer sizes.

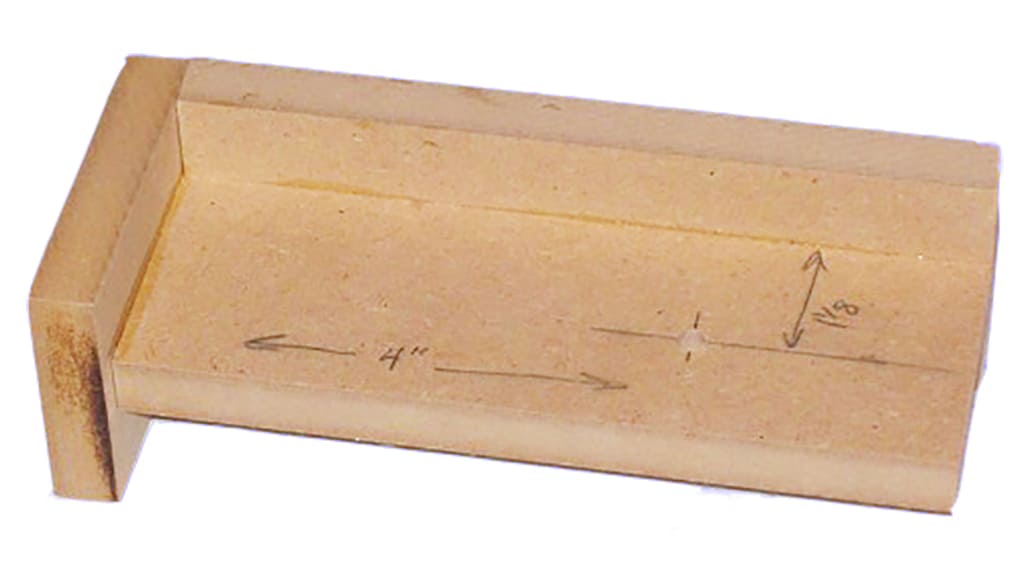

Templates come in two main types – custom-built and store-bought. Custom-built are typically built from MDF board or scrap plywood. To make and use a custom template, the user makes a decision about cabinet hardware placement, makes a corresponding hole in the template, then uses that hole as a guide for drilling cabinets or drawers.

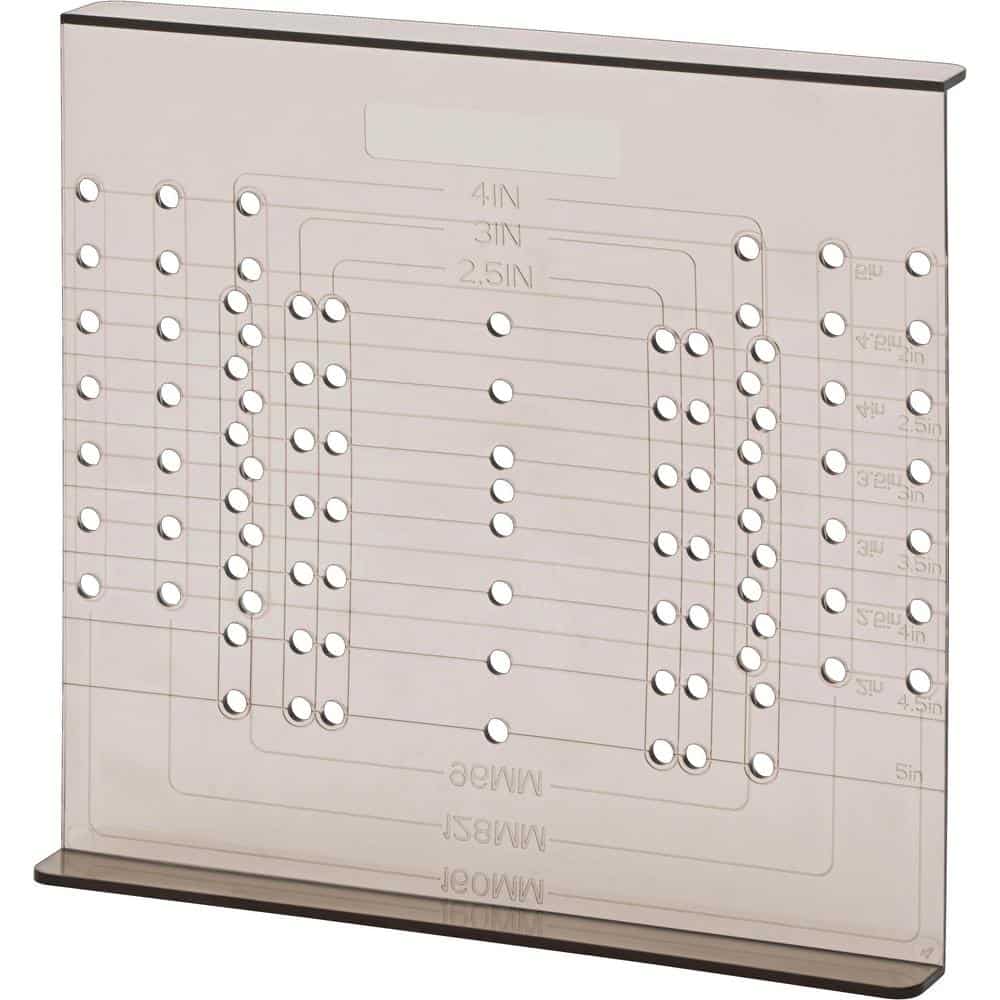

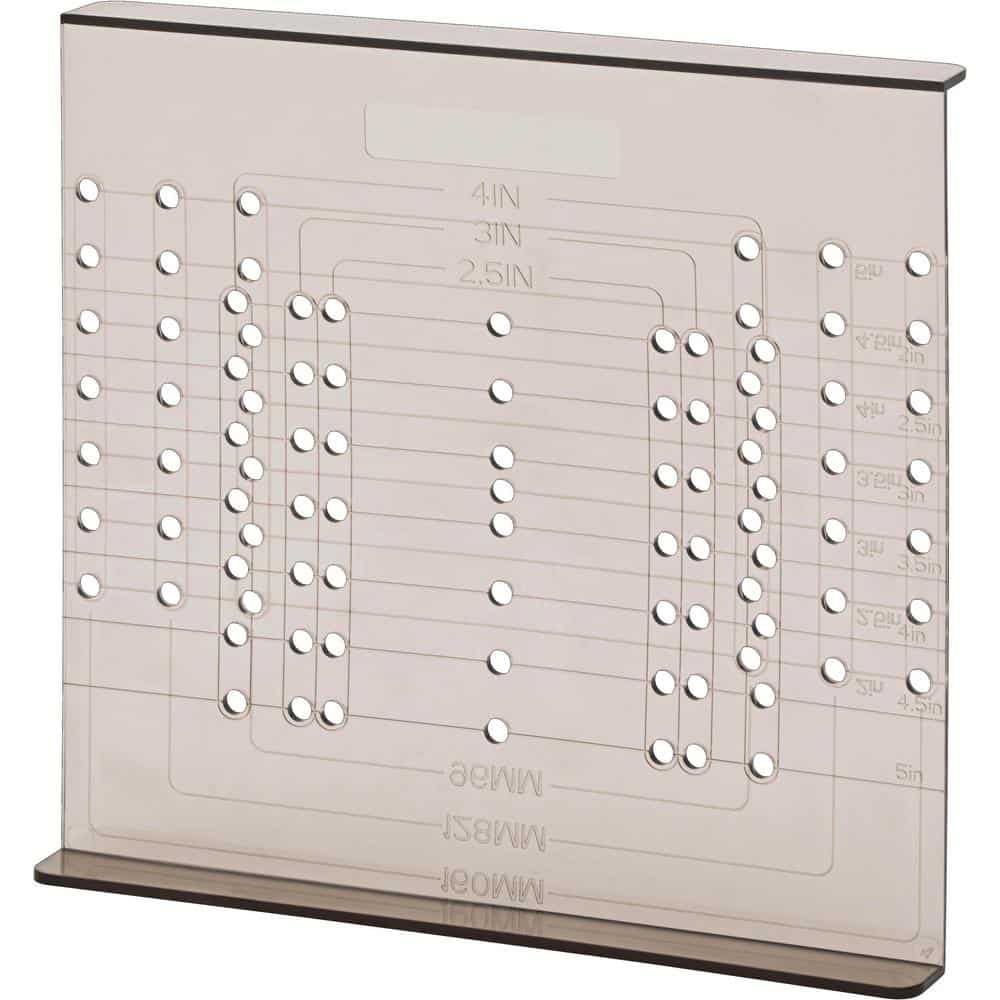

Store-bought templates tend to be a bit more sophisticated than custom-built examples. They are most commonly made of plastic, and typically have a number of different options for hole marking and placement.

The pros of templates include that they are simple and usually inexpensive. Custom templates can be designed and built to accommodate any type of cabinet hardware. Store-bought templates usually have an array of holes that are sized to work with the most common cabinet pulls, knobs, or handles.

The cons of templates vary based on what type of template is being used. Custom templates are usually purpose-built to assist in mounting one type of cabinet hardware to one particular size or dimension of cabinet. Store-bought templates, though they offer expanded options for hole placement, can only accommodate commonly available sizes of cabinet hardware and cabinet dimensions. A key detriment to templates of all types is that they aren’t durable over the long term. Over time, using the marking holes in a template as drill guides will cause the holes to grow in diameter, eventually leading to inaccurate hole placement.

Cabinet hardware installation jigs are precision tools that tend to be geared more toward the prosumer and professional market. Most common cabinet hardware jigs consist of a metal T-square and a few sliding metal attachments that can locked into position along the axes of the square. These metal attachments can have one of a few different purposes, such as serving as drill guides or as positioning stops. With a jig, the user simply needs to adjust the drill guides to match the mounting hole(s) in the hardware, then adjust the position stops until the hardware is at the desired location on the cabinet or door.

In terms of quality, durability, accuracy, and adaptability, cabinet hardware jigs are far superior to templates. The top-rated templates, such as the True Position Tools Cabinet Hardware Jig (TP-CHJ), have T-Square frames constructed from hardened aluminum and guaranteed square to within one-one thousandth of an inch. This ensures cabinet hardware placement that is straight, true, and visually perfect. Another benefit is that jigs are infinitely adjustable, to allow for flexibility in the homeowner’s choice of hardware or hardware placement. A third benefit, due to the hardened steel bushings that act as drill guides, is that hole placement will always be precise. Hardened-steel bushings allow for direct drilling through them, which keeps the drill bit at the desired location. A fourth benefit is that jigs are reversible, so the user can drill a left and right cabinet door without having to change any settings on the jig.

The only real con to cabinet hardware mounting jigs is that, on average, they can cost a bit more than templates. As they say though, you get what you pay for. A one-time investment in a quality jig will deliver many years of time savings, precise hardware placement, and ultimately, happy customers.

The True Position Tools Cabinet Hardware Jig ORIGINAL is the best bang for your buck option in our lineup. Install knobs and handles in seconds with the most accurate jig on the market. Perfect results every time on any cabinet door or drawer front.

Shaker Cabinets: Your Hardware Placement Guide Table of Contents Hardware cabinet placement is a critical part of bringing the aesthetics of a room together. But

The Most Accurate Way to Install Cabinet Hardware Table of Contents An easy way to have a home reflect your personal style as a homeowner

Cabinet Hardware Jigs vs. Templates – Which Is Best for Your Cabinet Business? There are many different variables to creating and running a successful cabinetry

How to Install Cabinet Door Handles Table of Contents Replacing or adding cabinet door handles is a great way to update a room. Modern, sleek

How to Install Handles and Knobs on Shaker Drawer Fronts Table of Contents Getting ready to install handles and knobs on your Shaker drawer fronts?

Frequently Asked Questions Here is a categorized list of the most frequently asked questions we receive. If you can’t find the answer you are looking

© 2024 True Position Tools. All Rights Reserved.

Looks like you haven't made a choice yet.