Cabinet Hardware Jig MAX

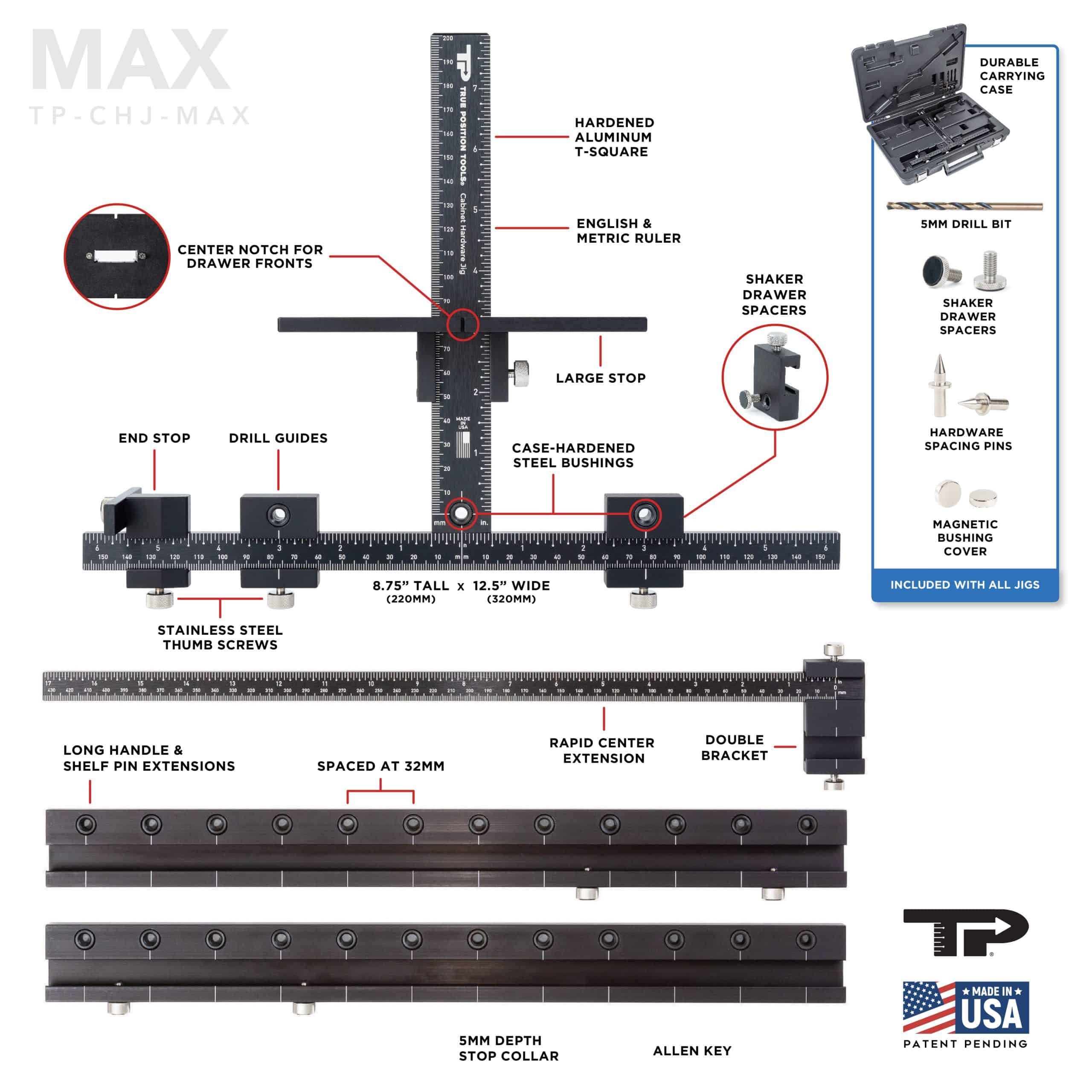

Install long pulls and shelf pin holes. Designed for drawer fronts up to 42″ wide and hardware up to 38” center to center.

Recommended by

CHJ MAX

Cabinet Hardware Jig MAX + Case

$299

Install knobs and handles in seconds with the most accurate jig on the market. Perfect results every time on any cabinet door or drawer front.

Includes the Rapid Center Extension for quick centering on drawer fronts and the Long Pull & Shelf Pin Extensions for hardware up to 38″ and shelf pins with 32mm spacing.

Free Shipping

On orders over $49 within the contiguous USA.

Money Back Guarantee

If this isn't one of the best tools you have ever owned simply return it for a full refund within 60 days of purchase.

Specifications

Lifetime Bushing Warranty

Instructions

Perfect Hardware Every Time

HOW IT WORKS

- Drawer Install

- Door Install

-

Set Hardware Spacing

Quickly and accurately space your hardware using our hardware spacing pins.

-

Set Location

Place hardware on cabinet to find the position you like, then simply transfer measurements to the jig.

-

Hold. Drill. Repeat.

No clamp needed! Simply hold and drill. Easily repeat on same-sized drawers/doors.

Built For Speed

Our Cabinet Hardware Jig doesn’t require marking or clamping. Created from a superior, hardened anodized aluminum that comes equipped with laser engraved rulers and case hardened bushings.

The Only Cabinet Hardware Jig For Shaker Drawers

Get the stability you need to drill into recessed panels with our patent-pending adjustable spacers.

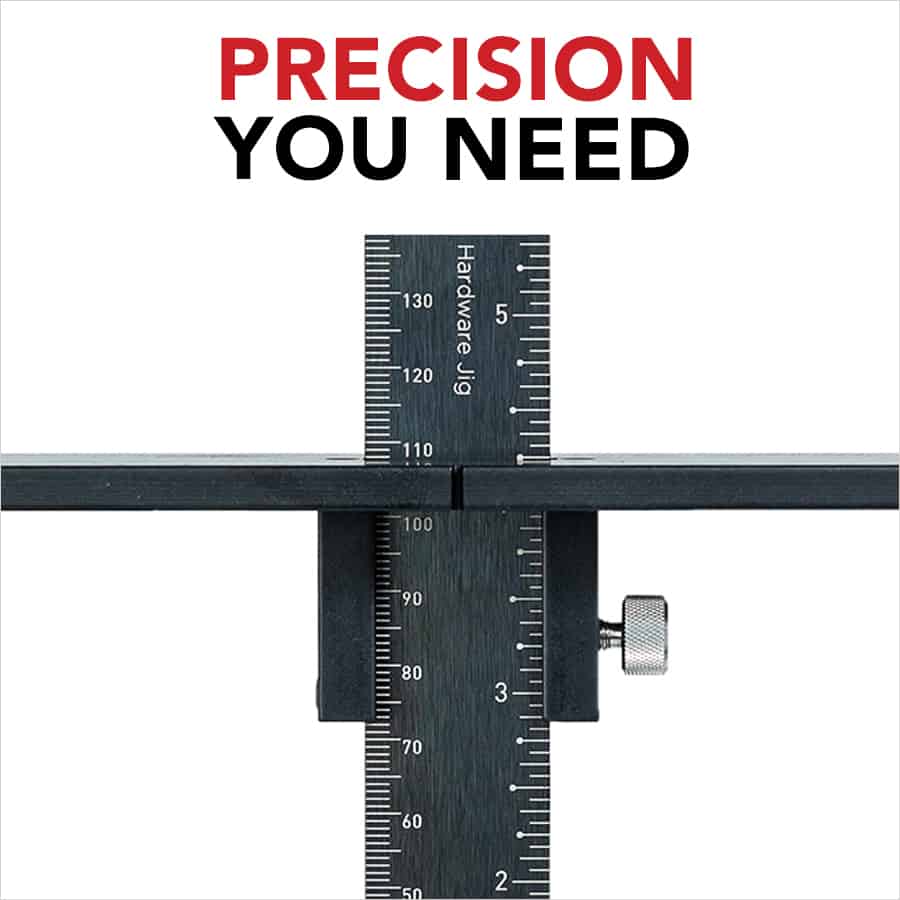

The Only Calibrated Cabinet Hardware Jig

10x more precise than imitations, with proven results you can count on. Patent-pending True Calibration™ system with Perfect Match™ laser engraved rulers. The most accurate cabinet hardware jig on the market.

Imitations Won’t Do

Our hardware jig is designed for the accuracy and durability you need. We hand assemble parts that are machined to ±0.0002” tolerance and then each completed jig is calibrated to .005” square. This can only be achieved using the highest grade materials and aerospace precision.

Pinnacle of Innovation

Developed and machined with an unprecedented grade of precision, durability and versatility. With such unique precision and robust build strength, the only tool that allows you to drill directly through it without the need for clamps or marking hole locations.

Premium Build Quality

- 3x Stronger Anodized Aluminum

- Lightweight, Strength of Steel

- Bushings Last 10,000+ Holes

- Laser Engraved English & Metric Rulers

Our “Precision Guarantee” promise is that each jig we produce adheres to our exact specifications, with the highest quality American parts.

If you receive your hardware jig and feel that it’s not one of the best products you’ve ever purchased, please contact True Position Tools within 60 days of purchase for a full refund.

What People Are Saying

"Saves hours on every single kitchen install."

"Gives you the ability to repeat perfectly whole layout from door to door, drawer to drawer--without worrying about wrecking the front of an expensive cabinet by poorly placed hole."

– Essential Craftsman

FAQs

Not at all! This tool is very easy to use and designed to take the frustration out of hardware installation for homeowners and cabinet professionals alike. It is used by many professionals due to its substantial time savings, unrivaled accuracy, and durability.

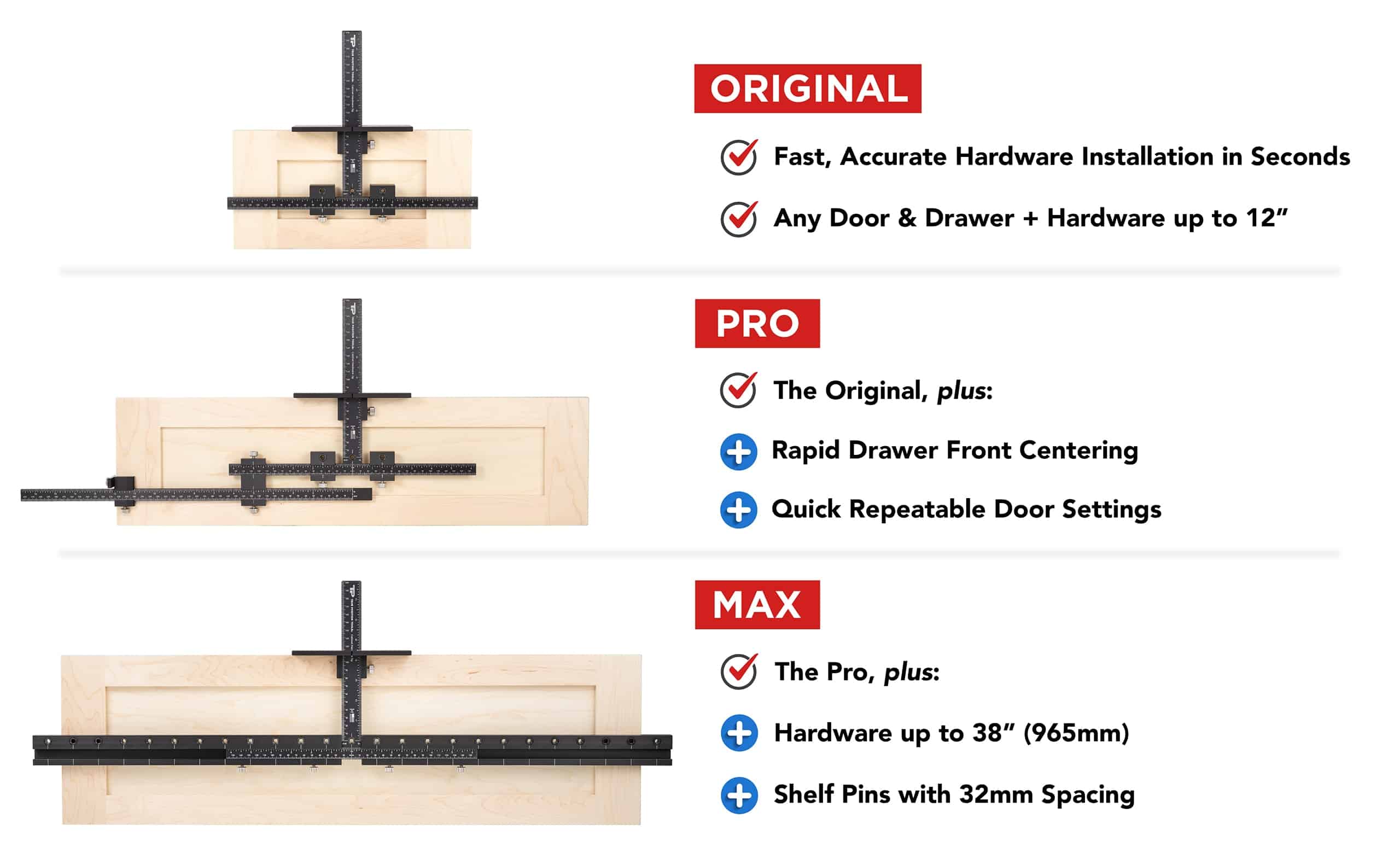

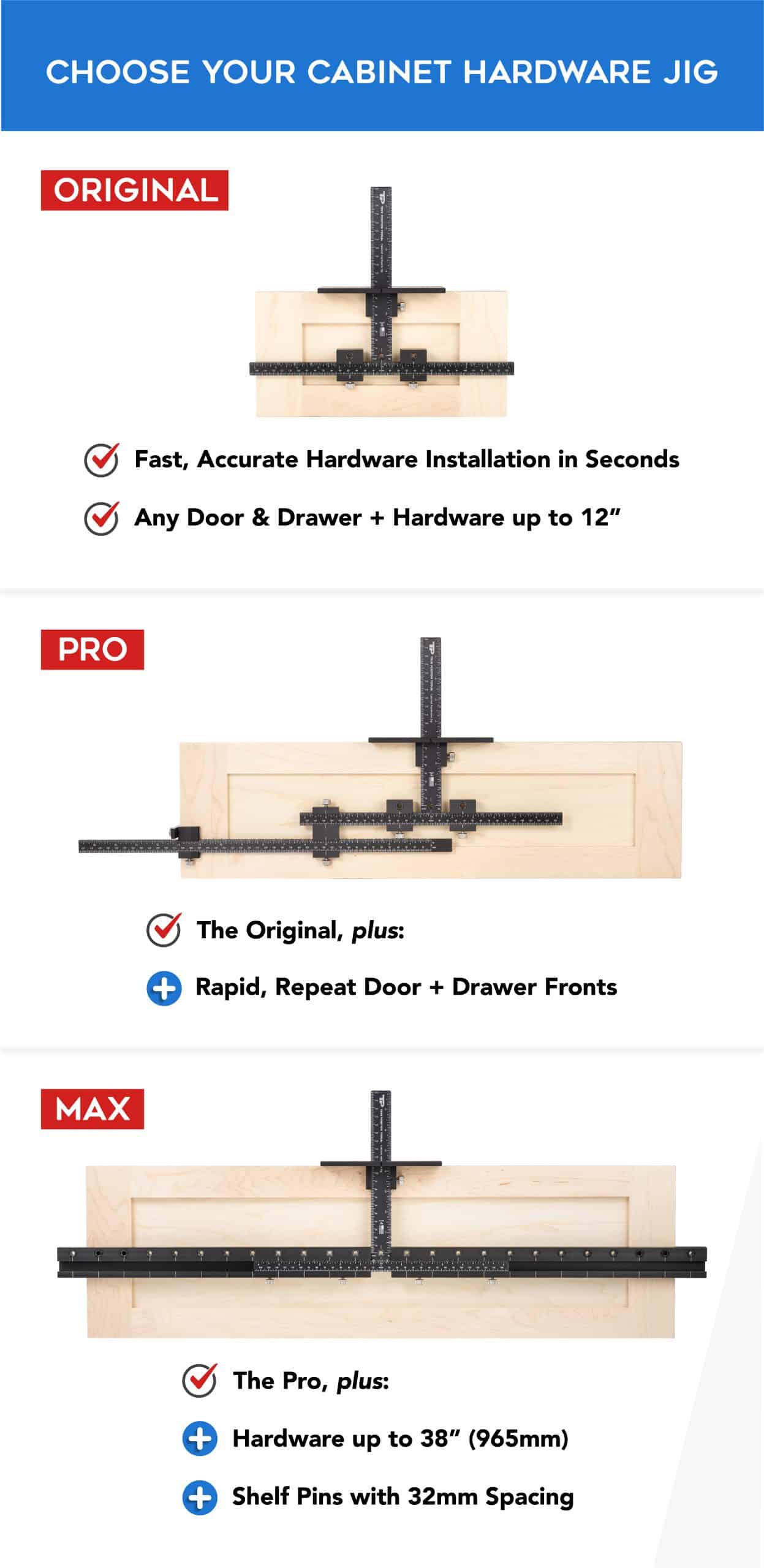

12” Center-to-Center (300mm) for the Original (TP-CHJ) & PRO (TP-CHJ-PRO)

For cabinet handles larger than 12″, purchase the Cabinet Hardware Jig MAX (TP-CHJ-MAX) to install hardware up to 38″ (960mm).

If you already own the Original Cabinet Hardware Jig (TP-CHJ), you can upgrade to the MAX with the Long Pull & Rapid Center Combo (TP-CHJ-LPRC).

For even longer pulls, multiple jigs can be conjoined via thumb screws to drill for any length of handle.

Yes! Just set up the tool for one door and you can flip and drill for the next. We recommend checking that your thumb screws are still tight before drilling the next hole.

Yes, our Cabinet Hardware Jigs now include our new Shaker Drawer Spacers (TP-CHJ-SDS), so installing hardware on Shaker drawer fronts has never been easier. Our specialized jig is the only tool available that can accurately and quickly help you install handles on the inset panel of drawers.

For more information, see our guide on Shaker drawer hardware placement.

If you previously purchased a Cabinet Hardware Jig and it did not come with Shaker Drawer Spacers, they are available for purchase.

Always make sure to start with a sharp drill bit. Generally chipping is not an issue with the provided drill bit. Extra precautions include taping the work surface with blue painter’s tape. For melamines and veneers, consider using a brad point bit.

True Position Tools has high-quality 5mm brad point drill bits available for purchase in our store.

Always use a sharp drill bit and relieve chips as you drill by pulling the drill out of the workpiece as it’s running to spin off excess wood chips. Do not apply much pressure while drilling, especially at the end of the hole. Holding or clamping a sacrificial block of scrap wood against the back of the door while you drill is recommended for extra protection against blowout.

In most cases, the screw head covers any minimal blowout. In extreme cases, where a screw head would not cover minimal chipping from the exit of the drill, users will drill the hole halfway with a standard drill bit, then use a tapered drill bit to finish the hole. To prevent drilling injuries, always be aware of where your hands are positioned.

1/2″ width — The small and large end stops can also be reversed if extra clearance is needed.

16″ — Be advised, it’s typically not preferred to place hardware on the center of a large drawer front as it can make it more difficult to open. In most cases, placing the hardware more towards the top of the drawer front is desired for operation and aesthetics.

Over the years, many! Changes to the jig include a larger top stop, more durable thumb screws, a redesigned end stop, and extending the bottom rail of the T-square by approximately 1”. We now also laser etch the numbers into the jig, where before we screen printed them over the aluminum T-Square. We are the only Cabinet Hardware Jig in Black! In recent years, the tool has started shipping in a hard plastic case instead of a cardboard box.

Every Cabinet Hardware Jig now includes an Accessory Kit that contains Hardware Spacing Pins, Shaker Drawer Spacers, and Magnetic Bushing Covers.

Yes! Every part of the tool is either covered under warranty or can be purchased separately. We have many commonly needed replacement parts available on our website. Please contact us here or call 760-279-3033 if you are having trouble finding the part you need.

Top (large) stop and T-square parts are only available as a set, as they need to be precision-mated in-house to a tolerance of .001” square for us to be able to guarantee their accuracy.

Color: Since 2017 we’ve been making our jig in “TPT Black”.

Calibration: Inside your case you’ll find a Certificate of Calibration with a unique serial number for your jig. On the jig itself, you’ll also find a protective sticker covering the two factory calibrated screws.

Laser-Etched Rulers: Our rulers are precision laser-etched which is a permanent etching. Imitation jigs are screen printed and can rub off with use.

Made in USA: True Position Tools makes the only Cabinet Hardware Jig that is made in the USA. Imitation jigs are crudely made overseas.

Share your thoughts!

4.86 out of 5 stars

151 reviews

Let us know what you think...

What others are saying

Thomas L Bingham (verified owner) –

After 53 years of building cabinets, this is the jig to own and use

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

CH ZITTING (verified owner) –

Professional grade. My only pick for drilling hardware.

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Carlos Cabrera (verified owner) –

Professional product, just buy, and you will be smiling at your new projects. very good

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Hector (verified owner) –

Everything work perfectly

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

David Kummer (verified owner) –

A most for quality cabinet work

Upvote if this was helpful (0) Downvote if this was not helpful (0) Watch Unwatch Flag for removal

Login

Continue as a Guest

Continue as a Guest